Your Trusted Partner in Metal Injection Molding Technology

An ISO 9001:2015 Certified Company

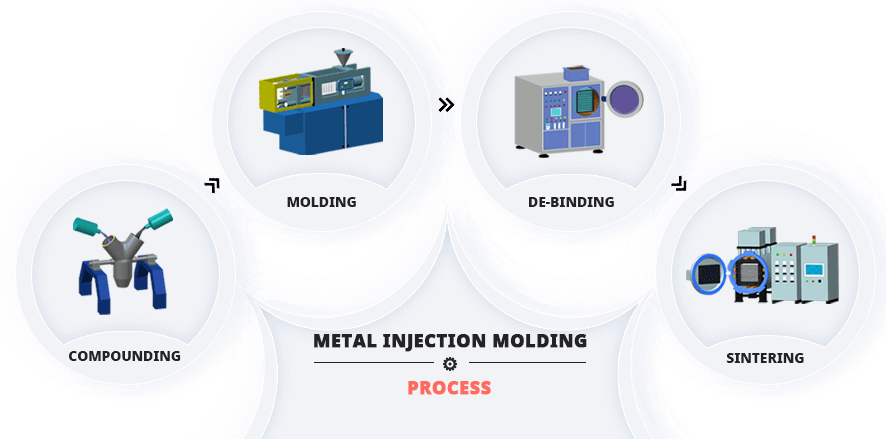

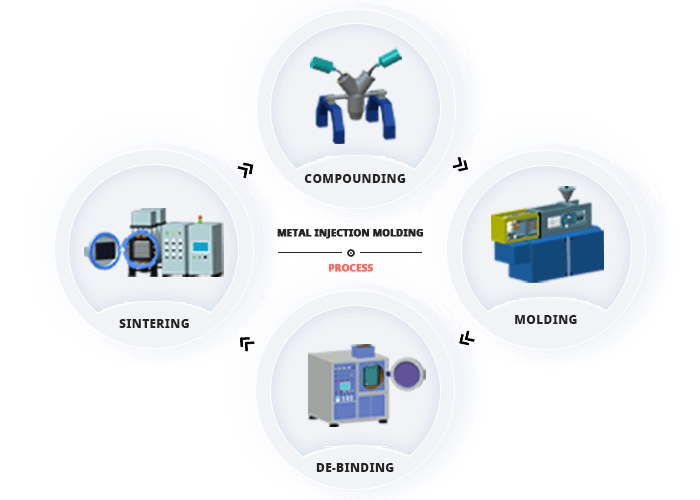

NNF TECH PVT. LTD. is a global supplier of Metal Injection Molded (MIM) components. Since its inception in 2013, we have established ourselves as a reliable partner providing solutions based on customer specific requirements. The state-of-the-art manufacturing facility located in Bangalore, India with design, engineering & manufacturing under one roof. We provide one stop solutions, and having our presence in more than ten countries.

We are a team of professionals with over a decade of experience in MIM technology. Committed towards quality we adhere to the best practices followed in industry.

NNF TECH PVT. LTD. provides end to end manufacturing solutions to the clients across the World, supporting them in innovation, growth and excellence.

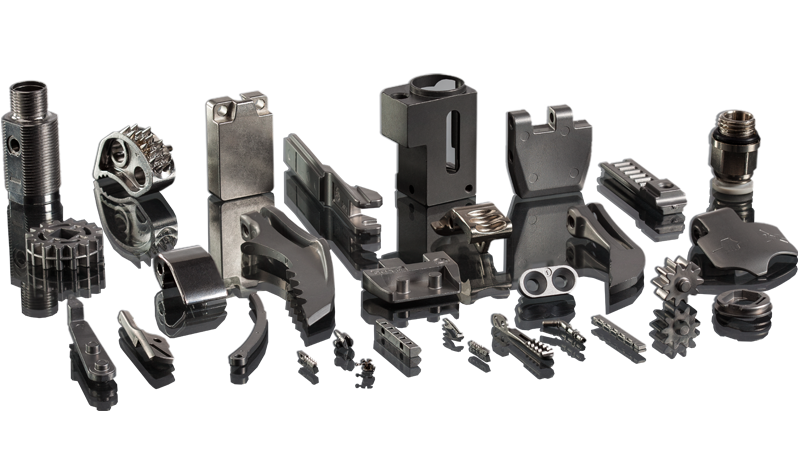

VARIETIES OF COMPONENTS

GLOBAL CUSTOMERS

COUNTRIES SERVED

YEARS OF MIM EXPERIENCE

VARIETIES OF MATERIALS

DESIGN FLEXIBILITY

SUPERIOR PROPERTIES

MATERIAL VARIETY

COMPONENT INTEGRATION

DIMENSIONAL ACCURACY AND REPEATABILITY

HIGH VOLUME PRODUCTION

COST COMPETITIVENESS